Thermoplastic Compounds and the New Definition of Material Flexibility

In the traditional engineering lexicon, "flexibility" was a physical attribute - how far a material could bend before it reached its breaking point. However, in the modern plastics industry, the term has taken on a far more strategic meaning. For today’s product designers and engineers, flexibility is the ability to bridge the gap between seemingly incompatible properties: strength vs. weight, conductivity vs. insulation, and durability vs. sustainability.

As global markets demand higher performance at lower costs, thermoplastic compounds have emerged as the primary vehicle for this new definition of flexibility. These materials are no longer just "plastic"; they are highly engineered solutions tailored to solve specific industrial challenges.

The Shift: From Commodity to High-Performance Engineering

The market is rapidly moving away from off-the-shelf resins. Industries ranging from automotive & transportation to electronics and telecommunication now require materials that can perform under stress while remaining easy to process. This is where the versatility of thermoplastic compounds provides a competitive edge.

Unlike standard polymers, these compounds are "alloyed" with specific fillers, reinforcements, and specialised additives. This allows manufacturers to:

- Replace Metals: High-performance compounds offer the structural integrity of aluminium or steel but at a fraction of the weight - a critical flexibility required for the next generation of electric vehicles (EVs).

- Consolidate Parts: By using custom plastic compounds, engineers can design complex, multi-functional parts that reduce assembly time and eliminate failure points.

Expanding the "Application Flexibility" across Sectors

The true power of modern compounding lies in its ability to adapt to diverse environments. Market leaders are no longer looking for a "one-size-fits-all" polymer; they are looking for a material that adapts to their specific sector’s friction points.

Electrical & Electronics: The Conductivity Paradox

Traditionally, plastics are insulators. However, the rise of smart devices and EV charging infrastructure has created a market for conductive compounds. By precisely integrating specialised carbon black, these materials offer the flexibility of plastic (complex moulding and lightweight) with the permanent electrical conductivity needed for ESD protection and EMI shielding.

Automotive and Appliances: The Aesthetics of Strength

In the appliances and automotive plastic additives market, "flexibility" means surviving extreme heat and chemical exposure without losing visual appeal. Engineering plastics, such as those offered under Plastiblends’ specialised "ENGITECH" brand, allow manufacturers to achieve high-gloss, UV-resistant finishes without the need for secondary painting - reducing both cost and environmental impact.

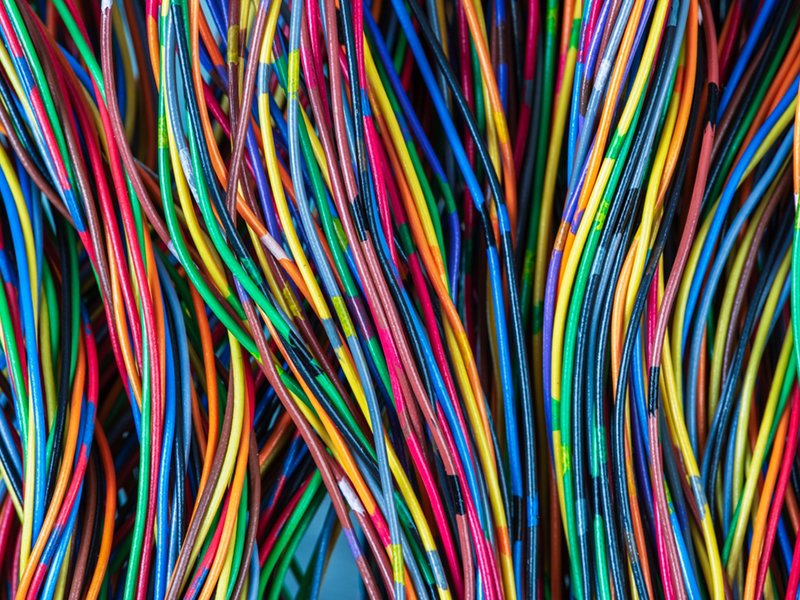

Infrastructure: Wire and Cable Resilience

For the wire and cable industry, flexibility is literal. Materials must be supple enough to be wound on spools yet tough enough to provide decades of cable insulation in harsh underground or outdoor environments. High-performance masterbatches and compounds ensure these cables remain flame-retardant and anti-corrosive without becoming brittle over time.

The Plastiblends Perspective: Engineering the Future

At Plastiblends, we deeply understand that the market doesn’t just need a material; it needs a solution. Since 1991, we have been at the forefront of the Indian plastics industry, exporting to over 60 countries. Our focus on Engineering Plastics Compounds is driven by this need for material flexibility.

Whether it is developing high-performance materials for healthcare and pharma or creating lightweight solutions for appliances, our commitment to R&D ensures that our plastic compounds meet the rigorous demands of an evolving global market.

Beyond the Bend

The new definition of material flexibility is about options. It is about the ability to choose a material that is exactly as strong, as conductive, or as sustainable as the application demands. As the plastics industry continues to evolve, thermoplastic compounds will remain the cornerstone of innovation, providing the versatility that allows modern engineering to push past its traditional limits.

- How Plastiblends Brings Colour Masterbatches to Life

- Masterbatches: The Backbone of Plastics

- How Masterbatches are Transforming Indian Plastic Industry

- White and Black Masterbatches Define More Than Colour

- How Flexible Plastic Packaging Is Redefining Consumer Convenience

- The Role of Black Masterbatch Manufacturers in Modern Plastics

- The Role of Filler Masterbatches in Effective Cost Control and Beyond

- Why White Masterbatch Manufacturers Are Key to Packaging and Product Aesthetics

- Inside the World of Flexible Plastic Packaging – Trends and Technologies

- The Role of Carbon Black Masterbatch in Modern Plastics

- From Automotive to Agriculture: Why Black Masterbatch Remains in Demand

- 5 Trends Transforming the Rigid Plastic Packaging Industry in the Long Term

- How Automotive Plastic Additives are Revolutionising Car Components

- Inside a Masterbatches Manufacturer’s Lab: The Science of Colour and Performance

- The PET Masterbatch Advantage in Modern Packaging

- The Rise of PP Masterbatch and How It’s Transforming Modern Manufacturing

- A Deep Dive into Carbon Black Masterbatch: Science, Applications & Innovation

- Inside the World of White Masterbatch Manufacturers

- The Real Reason Flexible Plastic Packaging Continues to Outpace Other Formats

- How Plastic Masterbatches Enable Consistency in an Inconsistent Market

- Thermoplastic Compounds and the New Definition of Material Flexibility

- Plastic Compounds and the End of Single-Property Plastics